BOBST reveals its Innovation Award winners for 2023

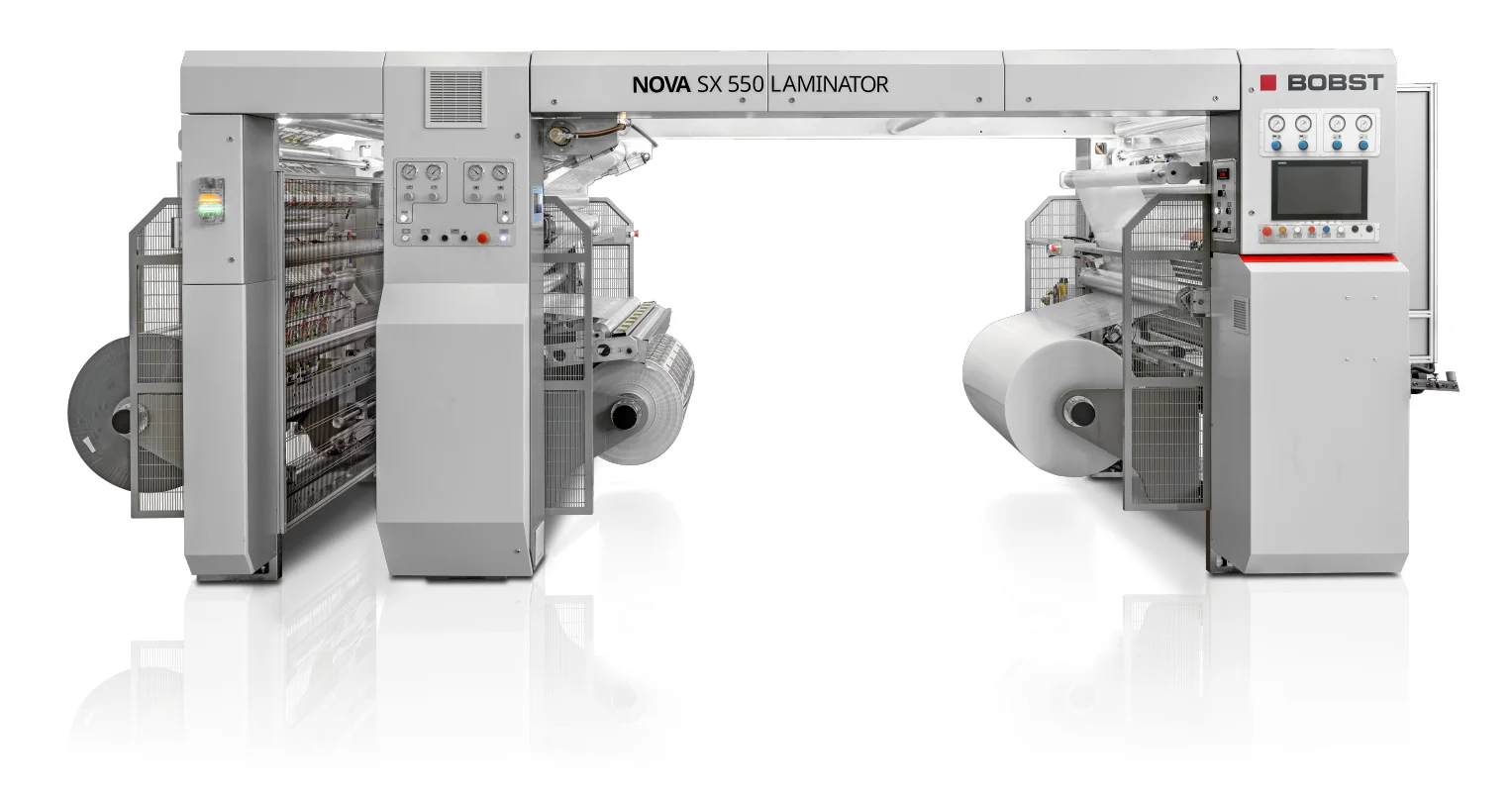

BOBST has presented its annual Inventor Awards, given to innovators and their patents within the business that have pushed the boundaries of technology to enhance print and packaging workflows for customers. For 2023, BOBST has issued two awards for the first time. The main Inventor Award has been presented to Patrice Chatry and Maude Steiner, inventors of the Non-Stop with Automatic Swords Selection innovation, while a Special Jury Award has been presented to Rene Heinze, inventor of an intermediate dryer in particular for rotary printing presses.

“We believe in expanding the boundaries of converting & printing efficiency, and each year we see BOBST engineers going above and beyond.” said Leonard Badet, Chief Technology Officer at BOBST. “Around the globe, our business is home to some of the industry’s most experienced and forward-thinking minds, making our customers production workflow more effective. This year we are thrilled to award 2 inventions supporting our Automation & Sustainability pillars. .

The Non-Stop with Automatic Swords Selection, created by Inventor Award winners Patrice Chatry and Maude Steiner, is a sheet pile supporting assembly. The device automatically selects which swords are used to temporarily sustain the pile of blanks in the separation station. With efficiency central to printing success, the key advantage of this patent is that job-dependent blank separation structures can be avoided, meaning a replacement pallet of blanks can be swapped in without stopping the machine and disrupting productivity. The innovation offers packaging converters a valuable time saving of six minutes per job, creating valuable gains throughout the workflow.

Presented with the Special Jury Award, Rene Heinze’s Dryer is a new geometry of intermediate rotary printing press dryer. The design features areas of both high and low pressure and comprises a novel system of nozzles and openings for the discharging of heated gas in exchange for cooled gas. In judging, the dryer was noted for presenting a 15% performance increase over conventional dryer designs, improving the yield of the overall drying process and making efficient use of hot air.

Christian Zeller, Head of Marketing BU Printing & Converting at BOBST, adds: “The printing and packaging supply chain is under pressure to deliver heightened quality, speed and sustainability. To meet these evolving demands, we must be bold in our innovation and find new ways to boost efficiency – and that’s what our Innovation Award platform is all about. We’re celebrating the talented minds of the BOBST team and the novel technology patents that make a real difference for our customers, which ultimately signpost the future of effective printing workflows.”

.jpg)

.jpeg)

.jpg)

.png)

.jpg)

_hw13rw8.jpeg)

Recent Comments